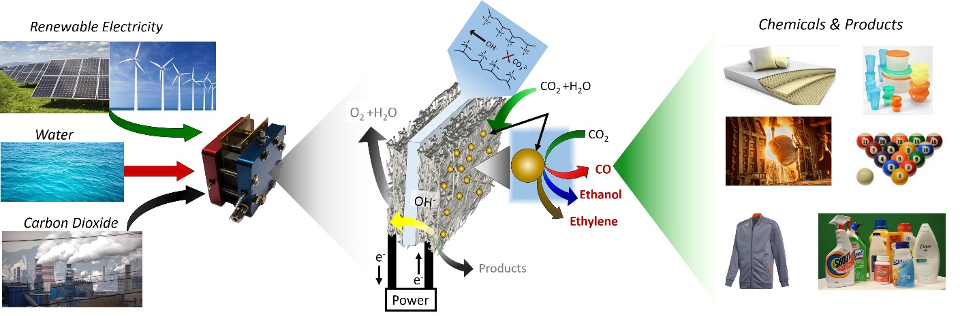

This project will develop enhanced electrolysis devices enabling CO2 to be converted into high value chemicals. Specifically this project will improve selectivity, efficiency and durability of electrochemical CO2 conversion into either carbon monoxide, ethanol or ethylene. The immediate focus will be on the highly economically attractive chemicals industry, with the long-term goal of using this as a steppingstone towards the fuels industry.

What is the challenge?

With 195 nations signing the Paris Climate Accord, the world has acknowledged anthropogenic induced climate change and the need for action. While fossil fuels accounts for the vast majority of the anthropogenic effects from CO2 emissions, they are used in diverse, but essential fields, such as heating, transport, power generation, industry and even as the primary raw material for the entire chemicals industry. While many of these fields have established sustainable options, there are others, which are at early stages of development which need rapid development to form the complete backbone of the energy system by 2030 and 2050. Currently 90% of the feedstock for organic chemicals produced in Europe comes from fossil fuels, leading to excessively high CO2 emissions (e.g. 2.3 Kg of CO2 is emitted for every Kg of ethylene produced). With the global chemicals industry producing 5.5% of all CO2 and 7% of all greenhouse gases (GHG), there are significant opportunities in this sector to use renewable energy to help the EU reach its 2050 mandate of reducing its GHG emissions by 80% from its 1990 levels. However, a recent EU analysis has shown that the best available technology today can only decrease GHG’s by 36%, thus demonstrating the need for breakthrough renewable energy solutions.

What is the proposed solution?

The drastic price drop in renewable electricity from sources such as solar and wind (93% and 64% in last 8 years, respectively) along with the mandate to significantly reduce CO2 emissions has now led to a new energy conversion opportunity: Sustainable chemicals production through electrochemical CO2 reduction (ECO2R). This process is effectively the reverse of a combustion reaction, where CO2 is combined with water to produces organics. Thus, ECO2R process is a net consumer of CO2, which will balance out the natural production of CO2 from oxidative decay or combustion of used chemicals, thus allowing for a CO2 neutral chemicals industry. While the ECO2R is uphill in energy, cheap electrical power along with an appropriate catalyst can allow us to accomplish this goal at an economically competitive price. This approach will take advantage of Europe’s high renewable electricity penetration and high-tech work force to create high value base chemicals (CO, ethanol, and ethylene) onto which the chemicals industry can use well-established processes to derive hundreds of others chemicals for various industries.

What are the expected commercial and societal benefits?

SELECTCO2 aims to establish the technological groundwork to allow for an electrification of the chemicals industry, which will entail cheaper, more environmentally friendly products. Besides being price competitive, electrochemically derived chemicals can provide buffer capacity to help mitigate intermittencies related to renewably generated electricity, thus decreasing the average electricity price to European consumers. SELECTCO2 will also benefit society through cleaner air, reduction in greenhouse gas emissions, and sustainably derived chemicals free of fossil fuel based contaminants such as mercury and heavy metals. Furthermore, the knowledge gained, supply lines developed, and infrastructure built in developing an electrochemical industry can be used as a stepping-stone to the much more economically challenging field of electrochemically derived fuels.