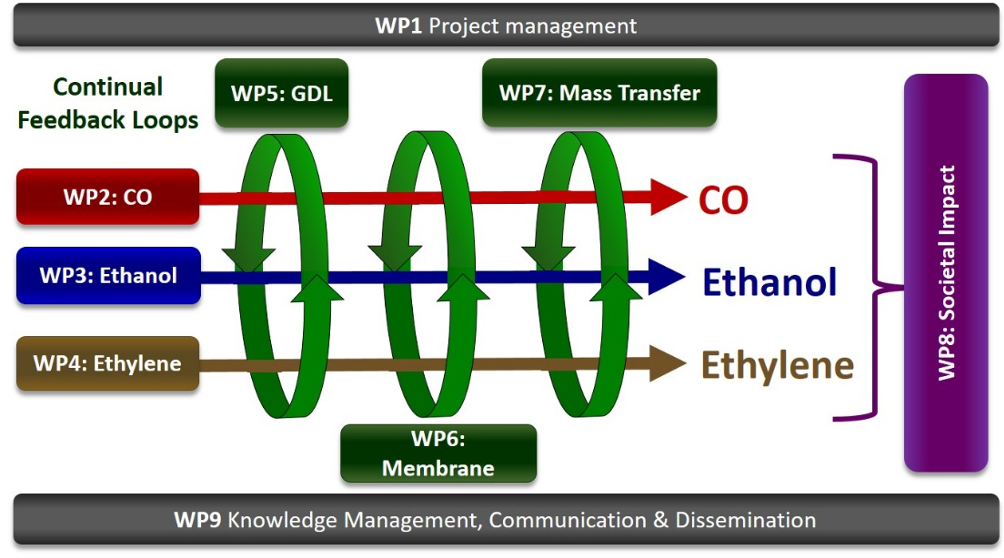

The overall methodology of this project is broken down into 9 separate work packages. The diagram below shows how all these work packages are connected.

Structure Overview

Work Packages Descriptions

WP1 - Project management & WP9 - Knowledge management, Communication and Dissemination

The project management will establish a strong working framework with quality control and risk mitigation to ensure tasks are finished on time and within budget.

WP2 - CO Production

Aims: TUB will focus on DFT studies, synthesis and characterization of carbon-based metal‐heteroatom‐doped carbon (MNC) catalysts, which will then be investigated for CO activity.

Outcomes: Efficient GDE devices producing CO at 90% selectivity with a device energy efficiency >50%.

WP3 - Ethanol Production

Aims: This WP will understand fundamental mechanism for CO2 to ethanol and use it to enhance performance.

Outcomes: Determine mechanist step where branching between ethanol or ethylene product occurs and achieve via a condensation process, achieve 80% ethanol selectivity in the condensate.

WP4 - Ethylene Production

Aims: The major aims for this WP will be to increase ethylene selectively by actively suppressing byproduct routes.

Outcomes: Improved ethylene selectivity (> 90% at 300 mA/cm2) in GDE type devices.

WP5 - Optimization of Gas Diffusion Layers (Lead: DENO)

Aims: The goal of this WP is to produce durable GDL/GDE with optimal mass transfer, conductivity and hydrophobicity/hydrophilicity for a given product.

Outcome: Establishment of an optimal pore size, hydrophobicity, and conductivity for CO, ethanol, and ethylene at currents >300 mA/cm2. GDE will achieve >200 hour stability with <15% change in selectivity.

WP6 - Optimization of Membranes & Ionomers

Aims: This WP will focus on analyzing and optimizing the conductivity and durability of anion exchange membranes (AEMs) and ionomers (AEIs) under various CO and CO2 reduction conditions.

Outcomes: Develop AEMs and AEIs with enhanced durability (> 200 hour stability with < 5% change in selectivity), higher ionic conductivity (10 – 100 mS cm-1) during CO2 (> 10 mS cm−1) and CO (> 100 mS cm−1) reduction.

WP7 - Mass Transfer & Localized Environment Effects

Aims: To use DFT calculations at the nano-scale and continuum-modeling on the meso- and macro-scale to allow for the creation of a multi-scale electrochemical device model.

Outcomes: The relationship of how electrolyte, electrode and environment affect catalysis activity will be established. This WP will guide the development an optimized device design and electrode structure for the best performing and most selective operation.

WP8 - Environmental, social and economic impacts

Aims: RINA-C will carry out a Life Cycle Assessment (LCA), Life Cycle Cost Assessment (LCC) and Social Life Cycle Assessment for CO, ethanol and ethylene.

Outcomes: A comparative analysis showing the potential strengths of ECO2R as well as the milestones this technology must reach to be economically competitive, environmentally beneficial, and socioeconomically advantageous.